Obviously this won't work on dark fabrics... for that you can use a discharge paste (to bleach the colour out).

I'm not able to make photo stencils yet, so the cheap and cheerful method is to use a cut paper stencil. I chose greaseproof paper (baking parchment) as it's easy to see a drawing through and doesn't disintegrate easily when wet. I also wanted to see whether fine details could be achieved.

Next up was preparing the printing mixture... I won't give specific amounts because I can't remember them! The thickener usually comes with instructions anyway. I used manutex to thicken water until it was gloopy. The dye concentrate was made up separately, and consisted of dye powder, soda ash, and enough water to make it liquid (there may have been salt too). Finally I mixed about a cup of manutex with a tablespoon or two of the dye, and added some calgon (to stop the mix being gummy and clogging up the screen). You can also use urea to stop the mix drying too fast (and clogging up the screen).

Now to print! I ran off lots of samples on different fabrics to see what would happen. On plain weave white cotton it printed perfectly, yay!

On un-scoured cotton calico the dye wasn't absorbed evenly, giving a distressed look, which I love! Sometimes it pays not to wash fabric first. :D I over-dyed it with tea afterwards.

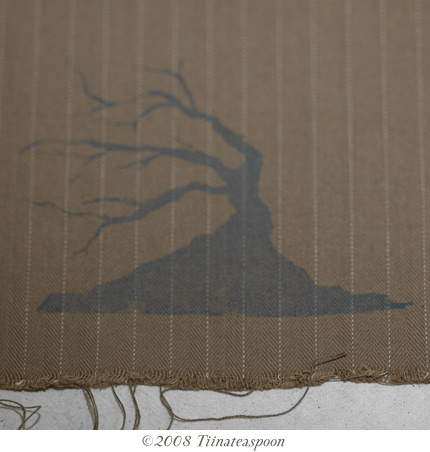

On thick cotton pinstripe the dye didn't penetrate fully, so the print looks faded (which I also love!) To print 'properly' on thick fabric I could have used a thinner printing mixture.

The print worked well on sheer cotton muslin too. The muslin was dyed first with walnut husks.

To set the dyes they needed to be steamed for 50 minutes, with the fabric rolled up in brown paper. I used an electric food steamer which worked pretty well (don't use it for food again afterwards though!)

Then a huge amount of rinsing and washing with synthrapol (fairy liquid does the trick too), a quick boil and they're cooked!

I've left some printed samples in a bucket of rusty things, hopefully they'll be ready in a week...

Fibrecrafts is a great website for print and dye supplies. They're UK based but ship worldwide.

Finally there's a great book I've been using to swot up on screen printing methods.

Screen printing: the complete water-based system by Robert Adam and Carol Robertson (ISBN 0-500-284253)

It doesn't cover print on textiles at all but if you're printing on paper etc. it's invaluable, for textiles it's still very useful. The methods of making up a screen are the same, and it has lots of juicy info on photo stencils. This book covers everything from the simplest paper stencil print, to setting up a professional printing studio.

No comments:

Post a Comment